Fred Hall & Son

Products and Services

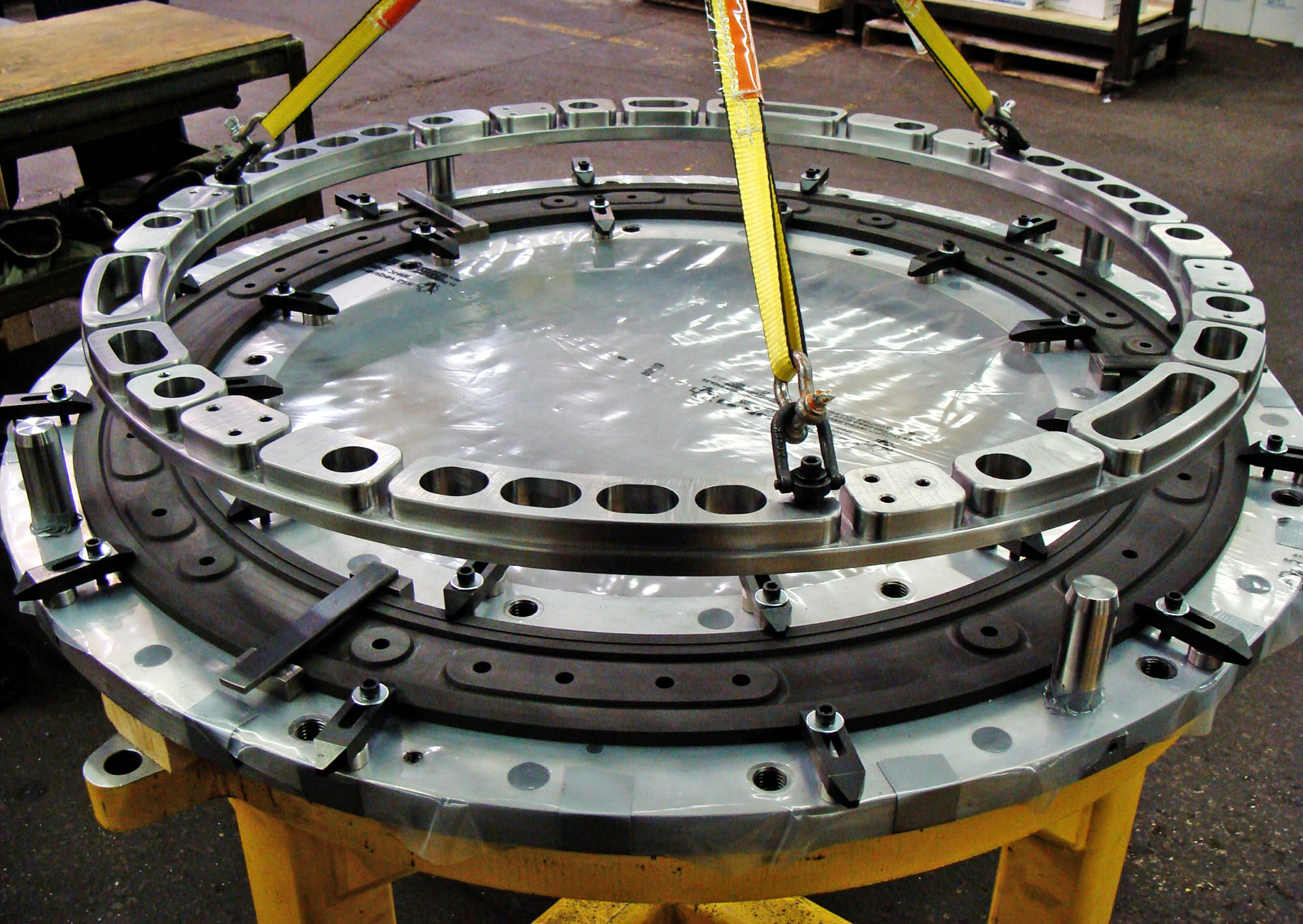

Our capabilities range from small one off parts to large complex assemblies. We are also equipped to provide contract machining for small lot production runs of complex parts. We strive to be an extension of your operations with intimate knowledge of the needs of your company and markets. Along with our extensive Boring Mill capacity, skilled workforce and comprehensive supply network we bring a willingness to work with you in order to help tackle the ever relenting demands of business today.

Industries Served

- Power Generation

- Custom Equipment

- Automation

- Nuclear

- Oil and Gas

- Fluid Power

- Mining

- Defence

Manufacturing Partnerships

Although companies have unique requirements, the one similarity they share is a need to be serviced properly. Reliable and dependable suppliers are essential in order to achieve superior performance and success.

With so many companies focusing exclusively on their core business, supplier excellence has never been so important. At Fred Hall & Son, we offer our customers our core business of machining and welcome the opportunity to become their manufacturing partner. Partnering with our customers ensures that their needs are consistently met, today and into the future. We have a vested interest in our customers’ success. It’s just the way we do business.

About Us

Equipment List & Production Capacities ⇓Our modern facility is equipped and staffed to produce complex components and assemblies.

Building: 30,000 Square feet

Crane Capacity: 10 Tons

|

HORIZONTAL BORING MILLS |

||

| Number of Machines | Description | Features |

| 1 Unit | TOSHIBA BP-150 R22 CNC 5 Axis 6.0” Spindle |

160” Cross Travel 120” Vertical Travel 60” Spindle Travel 86” x 71” Rotary Table |

| 3 Units | TOS WHN 13 CNC

4 Axis |

138″ Cross Travel 98″ Vertical Travel 49″ Spindle Travel 86″ x 71″ Rotary Table |

| 1 Units | TOSHIBA BTD 110 R16 CNC 5 axis 4.3″ Spindle |

78″ Cross Travel 59″ Vertical Travel 57″ Spindle Travel 63″ x 55″ Rotary Table |

| 1 Unit | TOSHIBA BTD 11 CNC 3 Axis 4.3″ Spindle |

78″ Cross Travel 59″ Vertical Travel 57″ Spindle Travel 63″ x 55″ Rotary Table |

| 1 Unit | TOSHIBA BTD 9 CNC 3 Axis 3.9″ Spindle |

48″ Cross Travel 40″ Vertical Travel 28″ Spindle Travel 36″ x 42″ Rotary Table |

| 1 Units | SHIBURA BF13 Floor Borer 5″ Spindle |

236″ Cross Travel 94″ Vertical Travel 36″ Spindle Travel 63″ x 63″ Rotary Table |

|

VERTICAL BORING MILLS |

||

| 1 Unit | SCHIESS CNC FANUC 18i-T Controller |

96″ Table, 108″ Swing 60″ Under Rail |

| 1 Unit | MORANDO CNC

FANUC OiTD CNC Controller |

144″ Table, 153″ Swing 72″ Under Rail |

|

TURNING |

||

| 8 Units | Various | 49″ Swing, Up to 26′ Long |

Fred Hall & Son is committed to a professional management approach that encourages and stimulates continuous improvement, in order to consistently meet our customer’s quality requirements. Fred Hall & Son employees understand and accept their responsibilities within the quality system. Our collective focus is to bring quality into everything we do.